Mining

Kasiya Graphite Produces Positive Tests Results for Refractory Applications

January 21, 2025 / Modester Mwalija

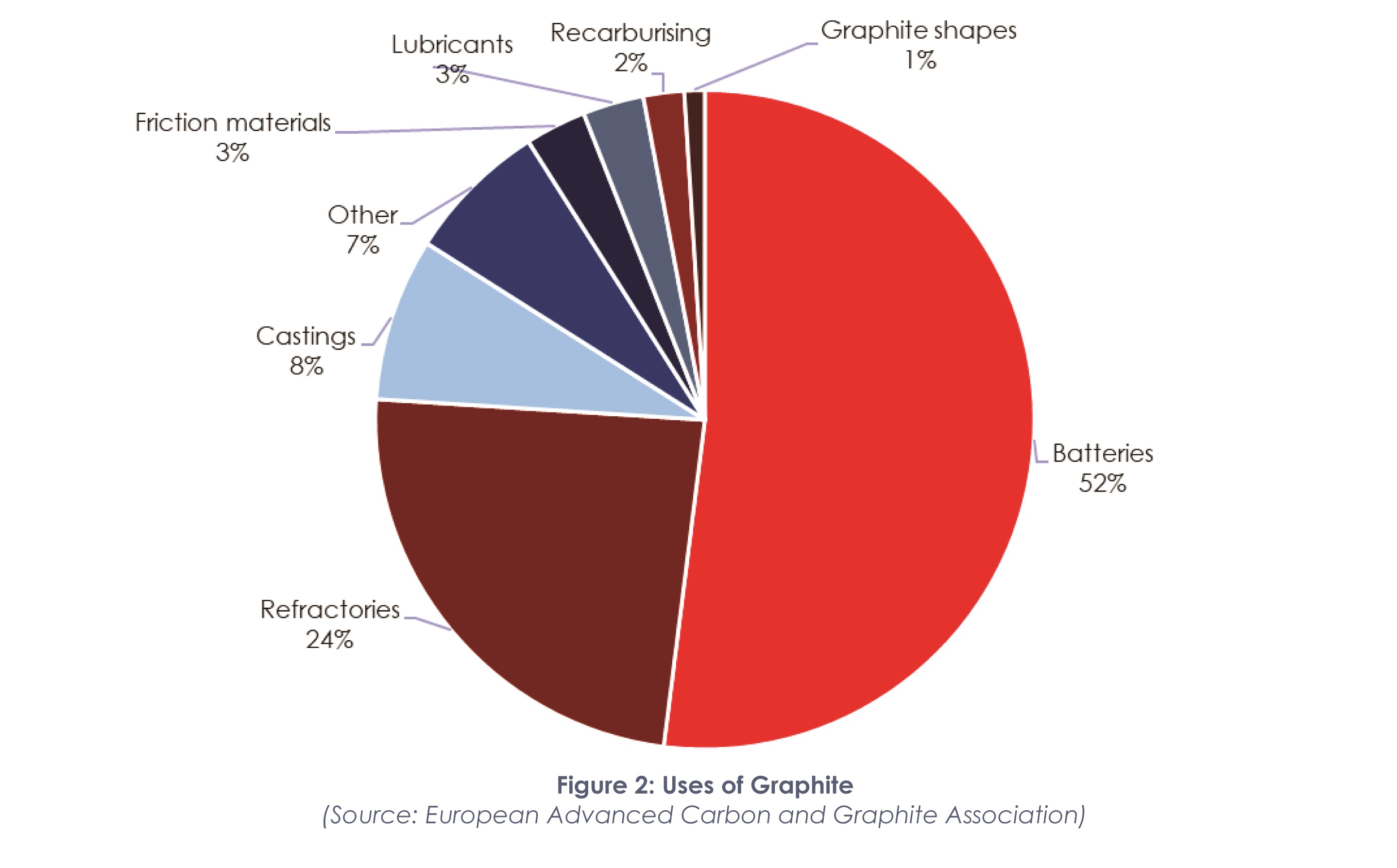

Uses of Graphite (Source: European Advanced Carbon and Graphite Association)

ASX-listed resources group Sovereign Metals says preliminary test results for graphite concentrate produced from its Kasiya Rutile-Graphite Project in Lilongwe have confirmed the suitability of the graphite for use in traditional refractory materials.

These tests, conducted by an independent consultancy ProGraphite GmbH in Germany showed the potential for Kasiya’s graphite to meet global demand in this industrial sector which accounts for 24% of global graphite demand.

Sovereign Metals MD Frank Eagar explains in a statement that the initial independent tests confirm that Kasiya’s coarse flake graphite (larger than 180 microns) has excellent oxidation resistance, with no oxidation occurring below 400°C and a mass loss of only 6.4% after four hours at 650°C.

He says this equates to a very low oxidation rate of just 1.6% per hour, making it suitable for applications in refractory linings used in high-temperature environments such as furnaces, kilns, and crucibles. Furthermore, Kasiya’s graphite boasts low sulphur levels (<0.02%), which enhances its appeal for refractory use by reducing the risk of corrosion and chemical instability.

"High resistance to oxidation and low levels of sulphur are two key attributes required to produce a premium graphite product for traditional refractory and foundry applications. Combining these attributes with the >50% large flakes of the Kasiya resource provides Sovereign with multiple marketing options," Eagar says.

Specifically, graphite is used to increase the effectiveness of the final refractory product by increasing thermal conductivity for efficient heat transfer, decreasing thermal gradient between the hot and cold faces of the product thereby reducing expansion, increasing the resistance to thermal shock which would otherwise lead to cracking or breakage of the refractory, low thermal expansion, reducing the ricks of structural damage and increasing the working life of the product.

Kasiya’s graphite is not just limited to the refractory market as previous studies have confirmed that the material can also produce high-quality anode materials for batteries, particularly for electric vehicles (EVs).

“This dual application of refractories and batteries provides Sovereign Metals with flexibility in securing offtake agreements and diversifying its supply chains,” he says.

Eagar reports that the company’s evaluation of coarse flake graphite for traditional applications will continue alongside optimization work for fine flake graphite. The goal is to generate comprehensive data that will support discussions with potential off-takers and position Kasiya as a competitive player in multiple sectors.

The findings come at a critical time as China, the world’s leading graphite producer that dominates the market by accounting for 75% of global flake graphite production and 96% of spherical graphite used in battery anodes, plans to tighten export controls on graphite and titanium alloys starting in December 2024.

"The reported restrictions further highlight the globally and geopolitically strategic nature of the Kasiya Project, which aims to become the world’s largest producer of high-grade titanium feedstock in the form of rutile and natural flake graphite," Eagar says.

As global markets seek to reduce reliance on Chinese exports, Kasiya’s development could play a key role in stabilizing supply chains while positioning Malawi as a significant player in the critical minerals industry.